Products

Case Packer (For pulp mold trays)

SMART Cube

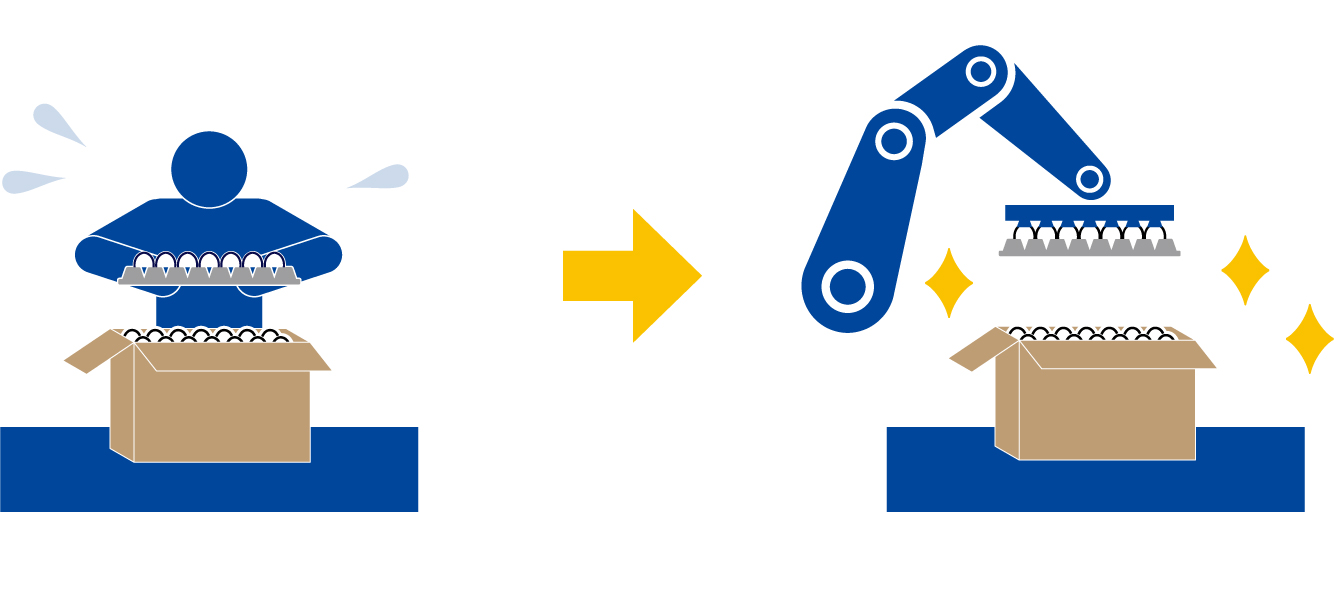

Automated tray packing

This machine places 30-eggs pulp mold trays containing eggs into cartons. It is very difficult to manually place 30-eggs pulp mold trays into boxes because they bend when they are lifted and the eggs easily crack when they come into contact with each other. The Case Packer automates this difficult task of packing eggs into boxes, handling the eggs gently.

Features

SMART Cube Series

Robots automate operations such as container supply, boxing, box stacking, and pack trolley stacking. Automation of labor-intensive tasks reduces the workload on site. In addition, because the robot performs the work, it is not dependent on the skills of the operator or the speed of the work, and stable performance can be expected.

Reduced workload

The robot effortlessly handles the packing process that originally require manpower. It reduces the burden on operators and ensures stable production on the packaging.

Lineup to suit your application

Two models are available, a 2 line type and a 1 line type, depending on the application on site.

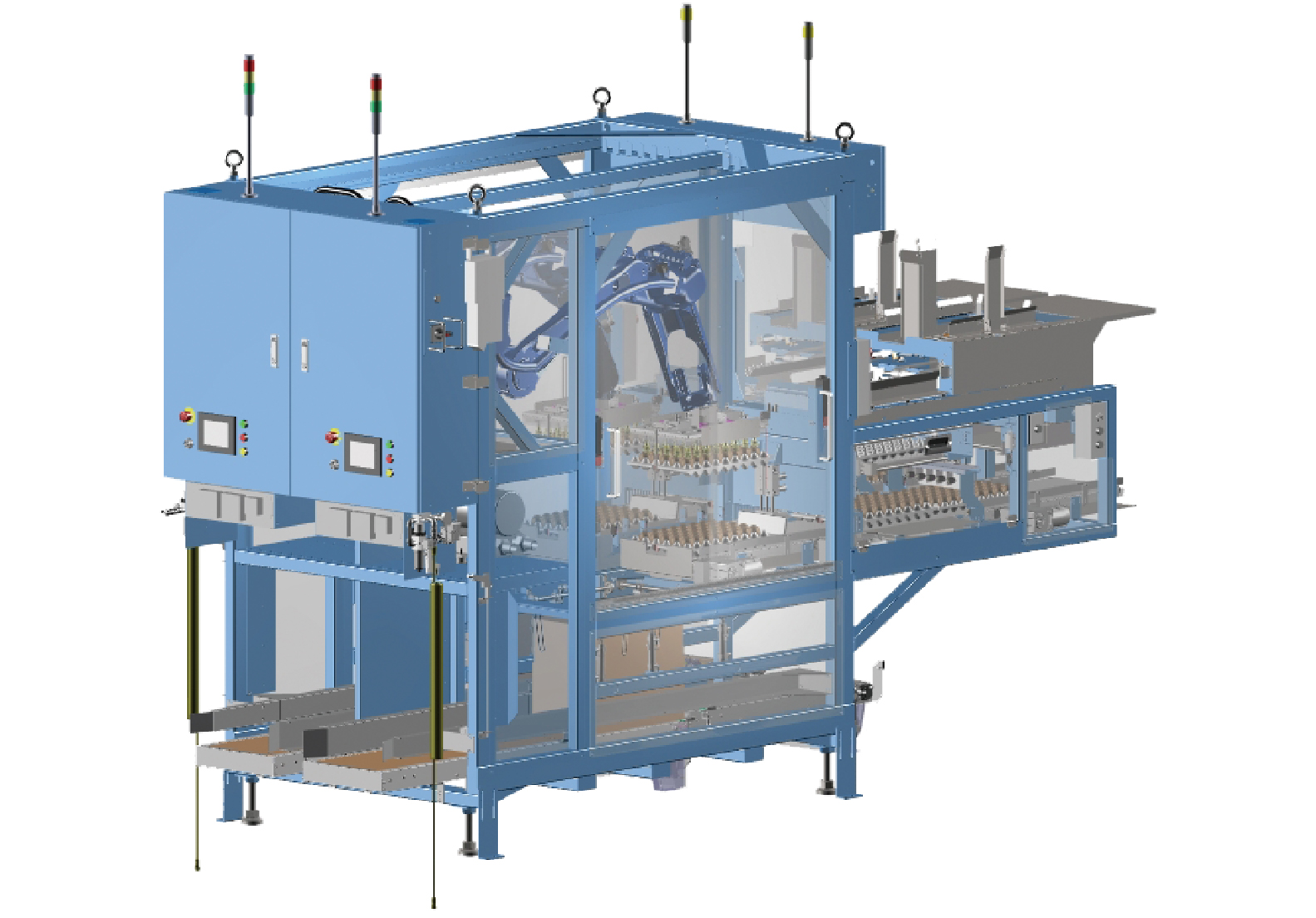

2 line type

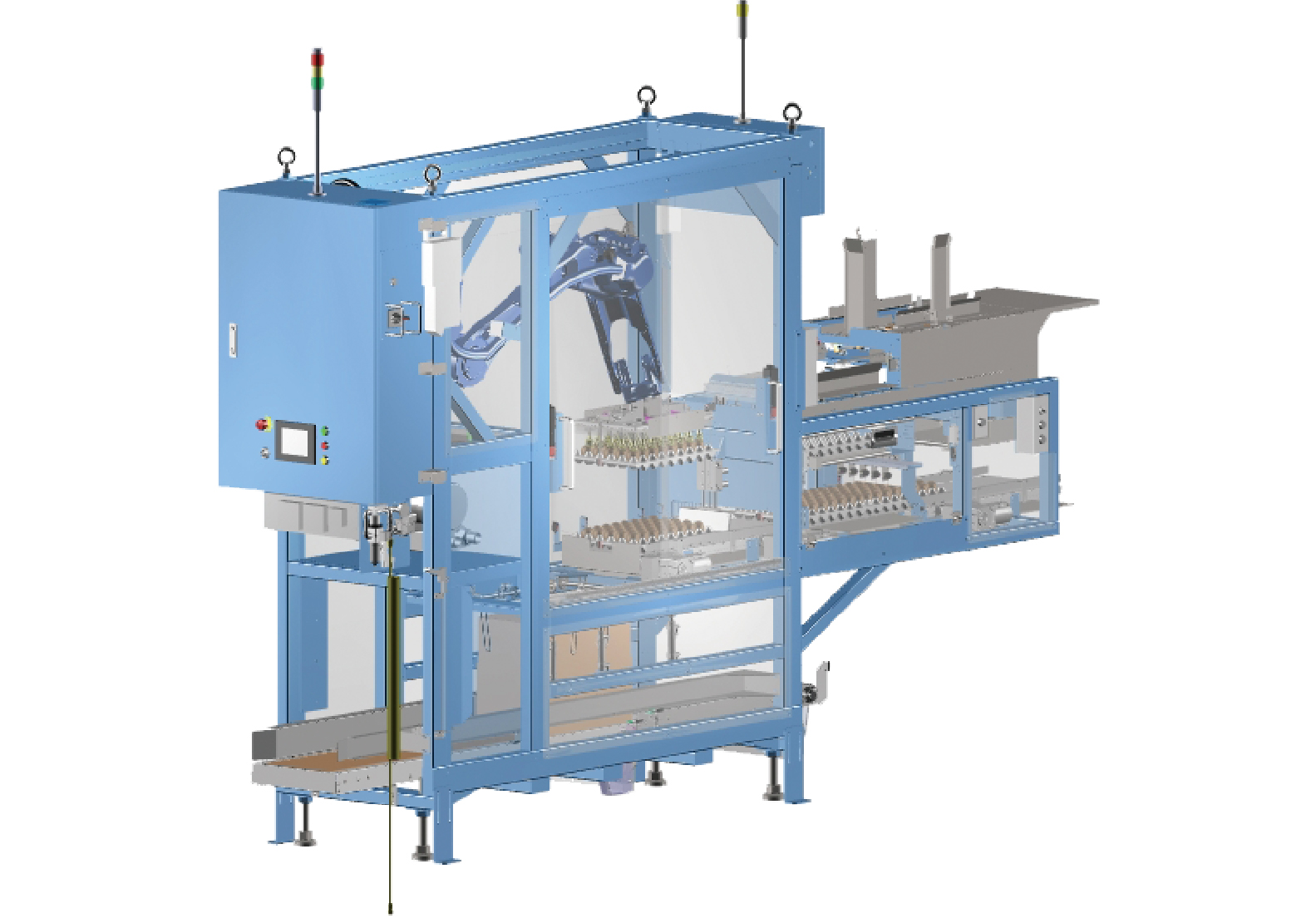

1 line type

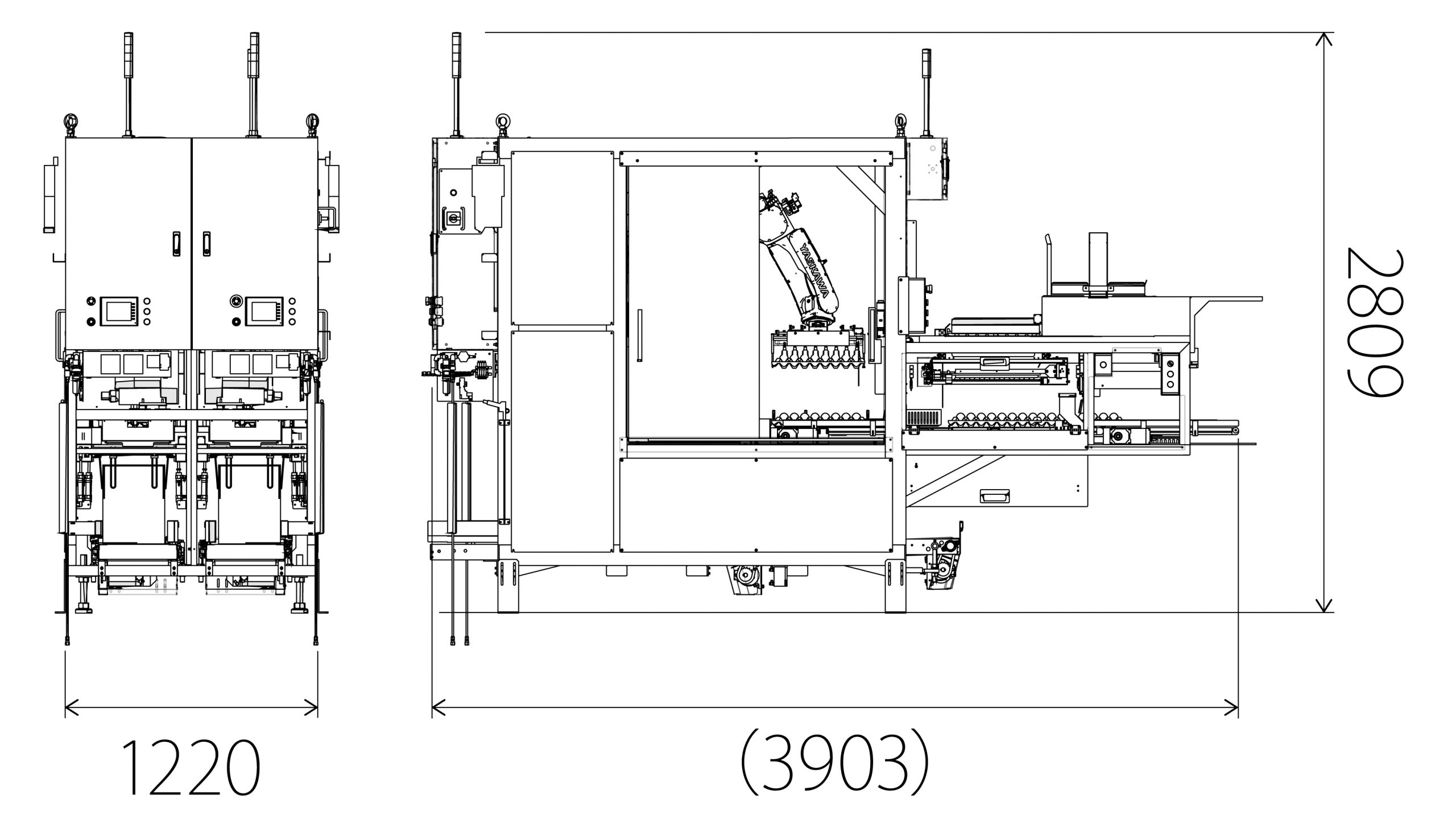

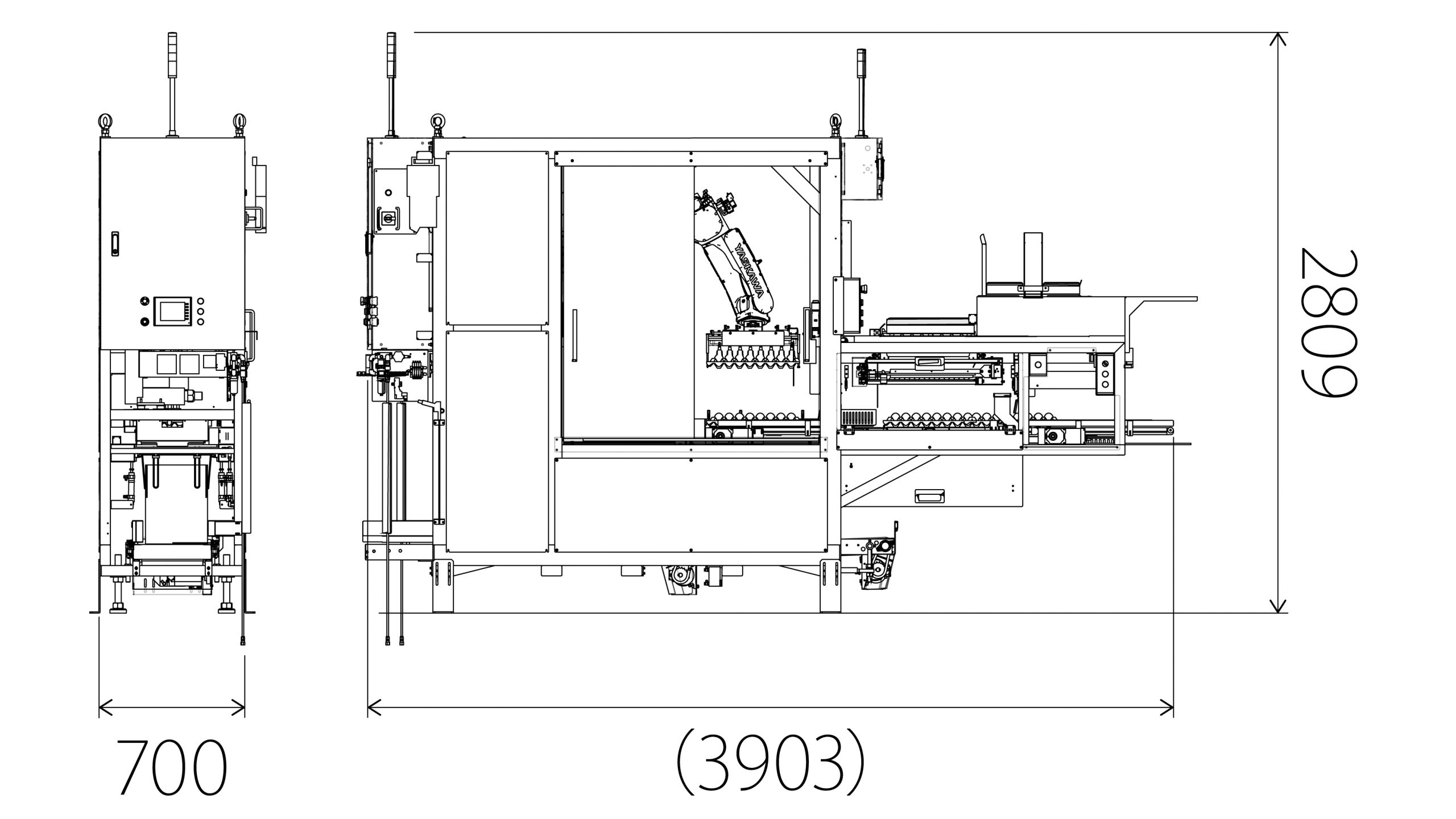

Layout

2 line type

1 line type

Specifications

| Code | 2 line type | 1 line type |

|---|---|---|

| Capacity (Max.) | 37,000 eggs/hr. *1 | |

| Power | 50Hz : 3-phase 200V 28.8A 60Hz : 3-phase 200V 26.4A |

50Hz : 3-phase 200V 14.4A 60Hz : 3-phase 200V 13.2A |

| Air consumption | 107L/min. (ANR) | 50L/min. (ANR) |

| Air supply pressure | 0.5 – 0.7MPa | |

| Working environment |

Temperature : 0 – 40℃ Humidity : 45 – 80% *2 |

|

| Available trays | 30-eggs pulp mold tray | |

| Available cases | Cardboard | |

*1 Processing capacity is per robot.

It varies depending on the number of eggs in the tray.

*2 No condensation

Designs and specifications are subject to change without notice.

It varies depending on the number of eggs in the tray.

*2 No condensation

Designs and specifications are subject to change without notice.